Anche quest’anno IPL ha partecipato attivamente all’evento organizzato dall’azienda e partner norvegese TESS a Fornebu, a pochi chilometri ad ovest...

Industrie Plastiche Lombarde

Azienda leader a livello europeo, specializzata nella produzione e distribuzione di tubi flessibili industriali.

IPL offre ai propri clienti soluzioni personalizzate, consulenza esperta e formazione costante, al fine di soddisfare le richieste più esigenti e fornire il prodotto piu’ appropriato all’applicazione.

I NOSTRI SERVIZI

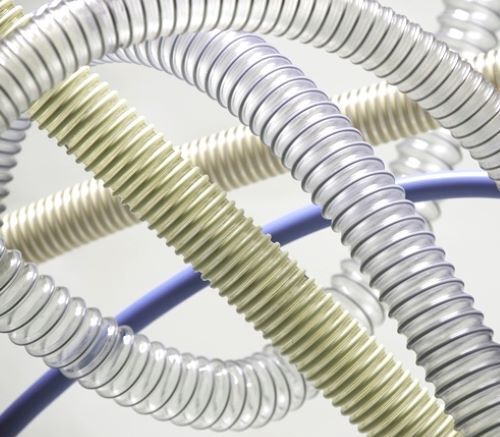

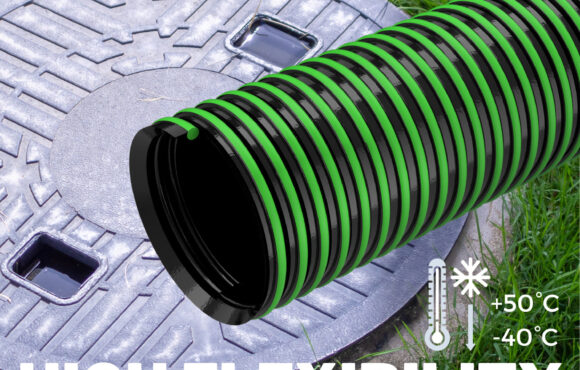

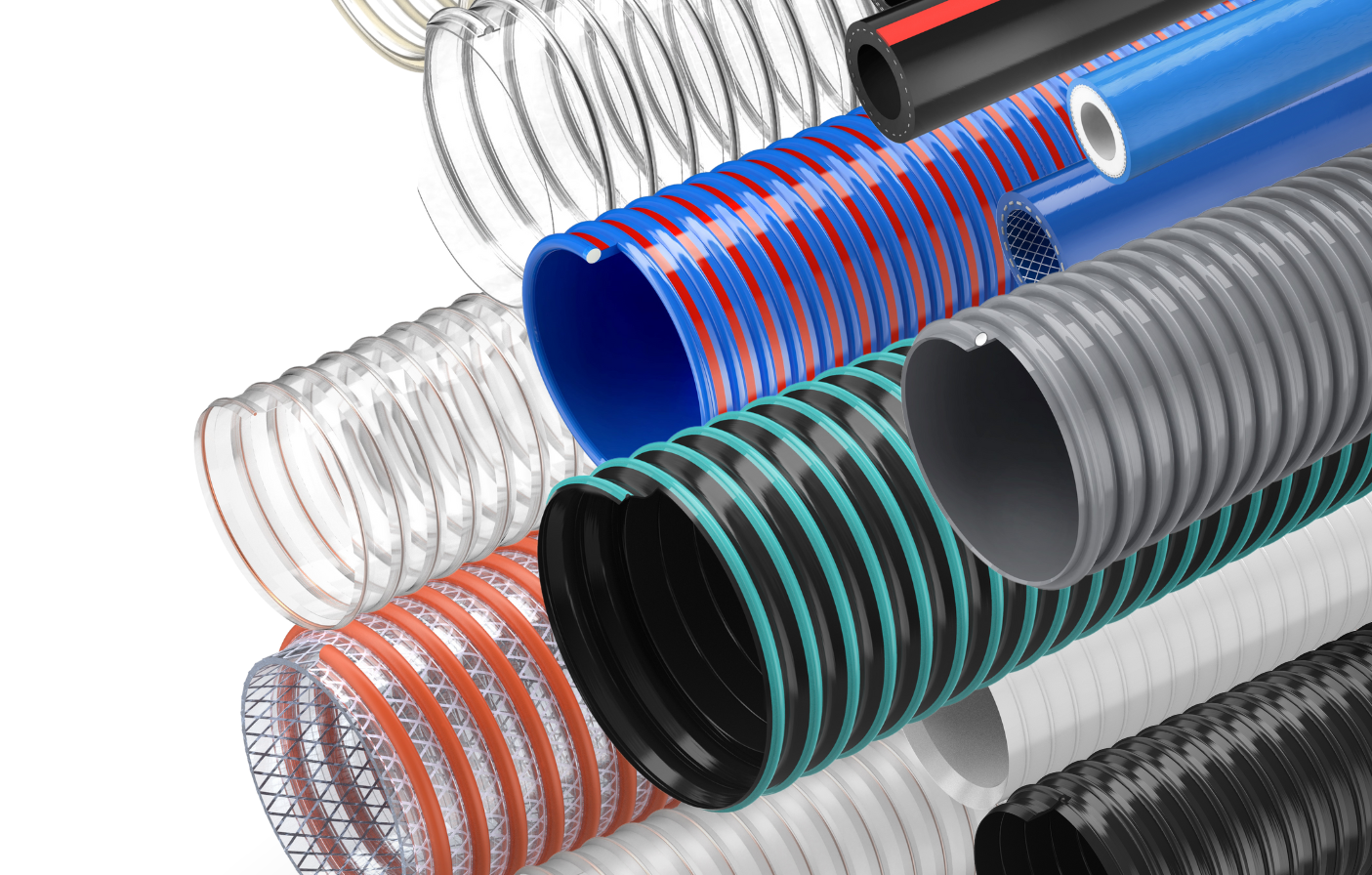

Una gamma ampia e completa di soluzioni flessibili

IPL offre un’ampia gamma di soluzioni flessibili, che comprende la maggior parte dei campi di applicazione all’interno di differenti tipologie di industrie: agricoltura, industria plastica,- lavorazione del legno, ventilazione e condizionamento, cantieristica navale, trattamento dei liquidi, industrie alimentare, farmaceutica e petrolchimica, sono solo alcune delle aree nelle quali operiamo.

NEWS

Da quasi 50 anni IPL opera nei settori industriale e alimentare, attraverso un’ampia gamma di prodotti,soddisfacendo i più elevati standard qualitativi e rispondendo con precisione, flessibilità ed efficacia all’evoluzione delle esigenge delle clientela

DISTRIBUZIONE

Qualità italiana garantita

IPL fornisce i suoi prodotti e servizi in oltre 100 Paesi, attraverso una rete distributiva capillare e con la propria presenza diretta, grazie a tre filiali: IPL UK Ltd, fondata da oltre un decennio nella regione delle West Midlands; IPL Industrial Hoses(Shanghai) Co. Ltd, inaugurata in Cina nel 2012 e IPL Mangueras Técnicas S.L., fondata a Barcellona nel 2020, per meglio servire il mercato spagnolo.

Nel corso degli anni l’azienda ha esteso i propri confini, portando in tutti i continenti la propria identità e consolidando i rapporti attualmente esistenti con i partners storici.

Oggi IPL prosegue nell’opera di rafforzamento della propria rete distributiva, al fine di garantire un servizio sempre più efficiente e capillare.

CONTATTI

Vuoi ricevere assistenza o richiedere informazioni?

IPL è certificata ISO 9001:2015 e da 10 anni ha implementato il proprio sistema produttivo nell’ambito della realizzazione di tubi alimentari e pharma, adottando le linee guida previste dalla certificazione GMP (Good Manufacturing Practises), in termini di processi, tracciabilità e controllo qualità.

La sede centrale e lo stabilimento produttivo sono situati a Besozzo (Va), su un’ampia area di 55.000 mmq, che include un moderno Laboratorio di Ricerca e Sviluppo e un magazzino di circa 7.000 mq.